AMS has also developed innovative technology for performance verification and condition monitoring of control rod drive mechanisms (CRDMs). With AMS’s “Full-Pull” testing technology, CRDM data can be analyzed over the full range of rod motion. Analyzing this data allows plants to verify the movement of rods for all insert and withdrawal steps, as well as identify rod misalignments and late latches due to CRUD buildup or other problems that may go undetected during traditional CRDM testing. Additional information on AMS’s “Full Pull” testing capabilities as well as all of AMS’s rod drop testing services can be found here.

Rod Control System Testing

Digital Rod Position Indication (DRPI) systems

For plants with Digital Rod Position Indication (DRPI) systems, AMS has simplified the testing process by developing the capability to measure rod drop times without de-energizing the DRPI system. Referred to as the “power-on” rod drop time measurement, this patented AMS technology saves nuclear power plants additional time and effort in performing rod drop time measurements.

Control Rod Drive Mechanisms (CRDMs)

AMS also provides equipment, training, and services for testing the timing and sequencing of control rod drive mechanisms (CRDMs). As with rod drop time measurements, we can perform CRDM testing on all rods simultaneously or on one bank of rods at a time.

Rod Control System Diagnostics and Troubleshooting

In addition to automated rod drop time measurements and CRDM testing, AMS provides rod control system diagnostics and troubleshooting. These technologies allow utilities to identify degradation or anomalies in the mechanical and/or electrical components of the rod control system including the rod position indication or CRDM coils, cables, connectors, and electronics.

Slave Cycler Timing and Sequencing

AMS also provides timing and sequencing verification of slave cyclers in the rod control systems of PWRs. Slave cycler timing and sequencing tests are performed to verify the signal timing of the slave cycler stationary, moveable, and lift logic cards in the rod control logic cabinet.

Combustion Engineering (CE) PWRs

For Combustion Engineering (CE) PWRs, AMS has developed a rod control testing and diagnostic system for the control element drive mechanisms (CEDMs) which has been implemented at Palo Verde, St. Lucie, and other CE (now Westinghouse) nuclear power plants.

AUTOMATED ROD POSITION INDICATION CALIBRATION TESTING SERVICES In PWRs with ARPI Systems

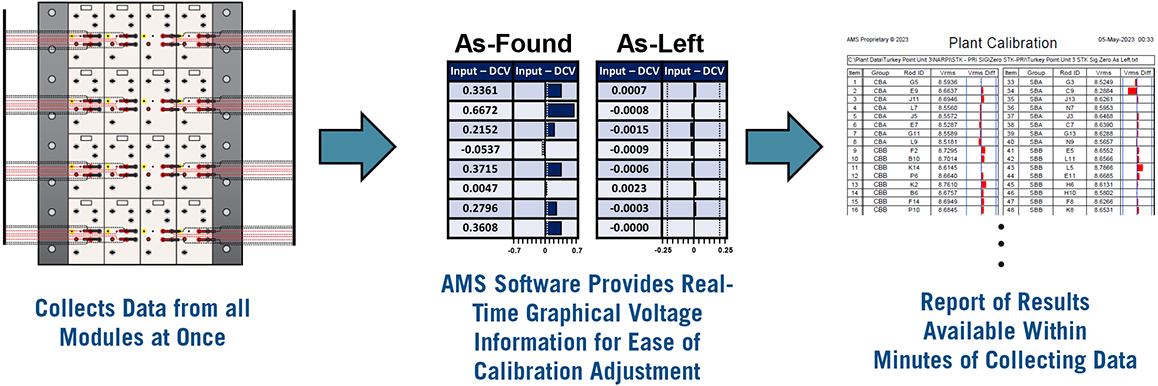

In Westinghouse Pressurized Water Reactors (PWRs), Analog Rod Position Indication (ARPI) systems are calibrated to ensure accurate indication of each ARPI module throughout the full range of control and shutdown rod motion. These calibrations involve monitoring the voltage outputs of multiple test points and making calibration adjustments when discrepancies are detected. This test is typically performed at normal operating temperature, pressure, and flow conditions.

Conventionally, ARPI calibrations are performed manually on one rod module or group of modules at a time. This is time consuming and often the tests are performed on critical path near the end of the refueling outage. To resolve these problems, AMS has developed a testing service that employs multiple automated ARPI calibration data acquisition systems that can connect to module test points simultaneously. Once connected, AMS testing allows for streamlined as-found/as-left data acquisition and provides real time voltage monitoring for module adjustments that need to be performed. The AMS service does not require any plant modifications, is easily set up, and significantly reduces test time.