AMS Completes DOE R&D Project on I&C Technologies for SMRs

AMS recently completed a seven-year multi-million-dollar research and development (R&D) project funded by the U.S. Department of Energy (DOE) which focused on the development of instrumentation and control (I&C) system technologies for small modular reactors (SMRs) and other next-generation nuclear reactors. In addition, AMS was also awarded two vouchers under the Gateway for Accelerated Innovation in Nuclear (GAIN) initiative which granted AMS researchers access to state-of-the-art facilities at the nearby Oak Ridge National Laboratory (ORNL) including the High Flux Isotope Reactor (HFIR) Gamma Irradiation Facility, the ORNL Thermal Hydraulic Test Facility, the ORNL Steam Plant, and the Advanced Cable, Cryogenic, & Superconducting Technology Development Facility. These resources, as well as AMS in-house facilities and equipment, were leveraged to perform experimental testing on I&C sensors and cabling exposed to harsh environmental stressors and SMR‑like operating conditions to establish their performance and survivability.

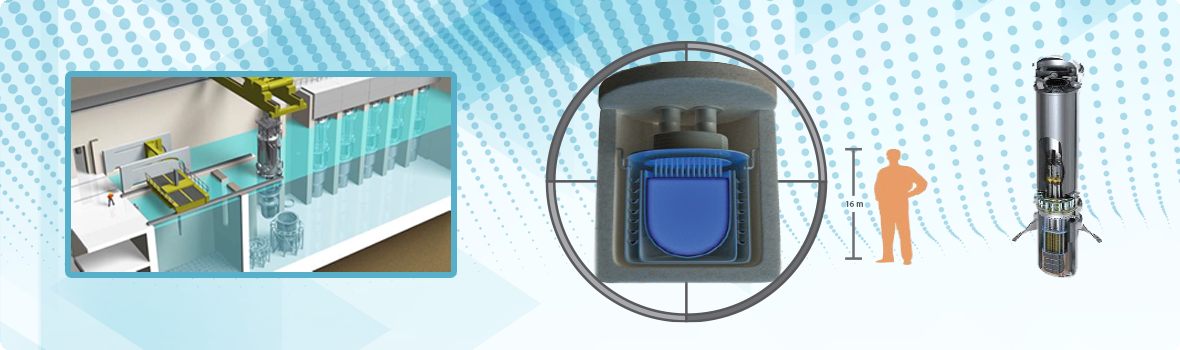

The sensors evaluated during this R&D included temperature, pressure, level, and flow sensors from existing nuclear grade instrumentation suppliers as well as emerging sensor technologies under development at national laboratories and industry organizations. The goal of this work was to determine the feasibility of each sensor for SMR and next-generation reactor applications taking into consideration their static and dynamic performance, in-situ testability, and long-term maintenance concerns. In addition to sensors, I&C cable samples were acquired and tested in high-temperature vacuum conditions, representative of the containment environment expected in the NuScale SMR. The I&C cable samples included in this study consisted of insulation materials commonly used in nuclear power applications such as silicon rubber, polyether ether ketone (PEEK), polyimide (Kapton®), and mineral insulations (MgO and Al2O3). The primary goal of this work was to establish derating coefficients for the cables that would ensure reliable long-term performance for SMR applications. Throughout the project, AMS worked with key stakeholders including NuScale, Holtec, TerraPower, Conax Nuclear (Mirion Technologies), Kulite Inc., Idaho Laboratories Corporation, and Sporian Microsystems among others to ensure the R&D effort served to advance the state of the industry. Publicly available information on this work can be found on our publications list.

As a result of this DOE award, AMS successfully developed and validated methods and technologies to verify the in-situ performance of I&C sensors and cables in SMRs. In particular, AMS developed a procedure to test safety‑related temperature sensors in the NuScale SMR at Shutdown, Startup, and Power to confirm plant technical specifications are satisfied. In addition, AMS built specialized laboratory test facilities including a high‑temperature vacuum chamber, based on input from ORNL and feedback from industry partners, to continue cable derating work in support of I&C cable specification for SMR and next-generation reactor applications.

Although SMRs and other next-generation reactors are still several years from deployment, the I&C expertise and products resulting from this R&D will be leveraged by AMS to support their initial startup and long-term operation. To that end, AMS has begun offering laboratory I&C testing and consulting services to SMR and other next-generation reactor developers.

For more information, please contact us at info@ams-corp.com.