To address this, AMS has developed an NI testing program for Source Range Monitors, Intermediate Range Monitors, and local power range monitors (SRMs/IRMs/LPRMs) in BWRs and ex-core nuclear instrumentation in PWRs to help identify NI circuit problems prior to any operability impacts.

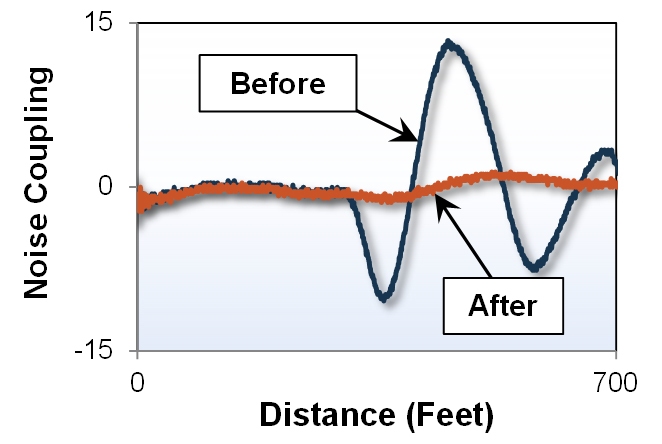

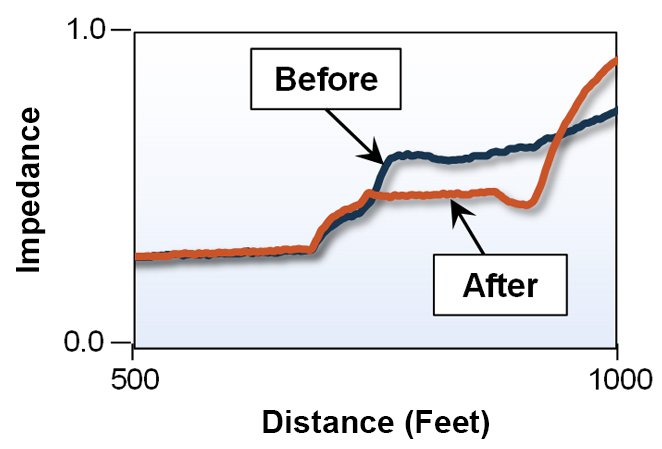

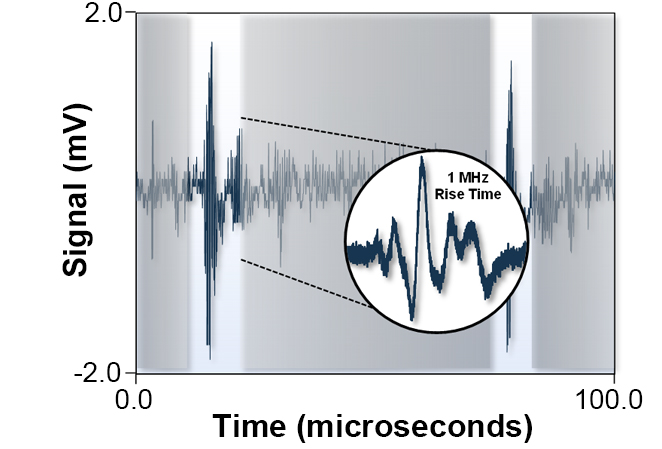

The AMS approach employs periodic health checks made through electrical measurements of each detector and its cable and connector properties. These measurements are performed remotely from the control room area using AMS’ Cable Characterization System (CHAR). This integrated test unit has been used in numerous nuclear power plants over the last 30 years to both identify and determine the precise location of problems in NI circuits.